35: TRANSFORMATION OF PROPERTIES

The Parameter Change principle refers to a concept where the value of a certain parameter or characteristic of a system or product is intentionally changed to achieve a desired effect. This principle involves manipulating key parameters to improve performance, overcome limitations, or find innovative solutions to problems. The essence of the Parameter Change principle lies in recognizing that altering specific parameters can lead to significant improvements or breakthroughs in a given system. By deliberately changing or adjusting certain factors, engineers and innovators can find ways to enhance functionality, efficiency, or overall performance. Recognizing the critical parameters or characteristics of a system that are relevant to the problem at hand. Deliberately changing the value or state of identified parameters to achieve a specific goal or address a particular issue. Evaluating the impact of parameter changes on the overall system and identifying how these alterations contribute to the desired outcome. Generating inventive solutions by considering alternative values, states, or combinations of parameters.

A:. Change the physical state of the sysetm

B: Change the concentration or density (or consistency or intensity)

C: Change the degree of flexibility (shape, structure or phase specific dimensional properties)

D: Change the object’s temperature and/or other physical properties such as volume, pressure, density, inductance, capacitance, viscosity, radiance etc.

E: Change the operational effect or properties by varying the chemical compositions or properties – formulation, pH, solubility etc.

F: Change the order of occurence of actions or operations (introduce serial-position effect, Introduce peak-end effect)

G: Consider the full spectrum of properties, states of transition, interfaces, etc., as a set — not in isolation — for the transformation, parameterization, or configurations of the system. (eliminate essentialism).

EXAMPLE: Ice or Sugar Cubes, Washing Detergent Cubes, Freezing the liquid centers of filled candies and then dipping into melted chocolate, Transporting petroleum, oxygen and nitrogen as liquid instead of gas, Liquid Soaps , Powedered Milk or Medicines or Paints (later to be converted into liquid just in time prior to the use), Alcoholic Beverages, Medicines, Seal-Ink, Vulcanized Rubber , Adjustable Dampers, Thermostat, Liquid-Liquid Separation, Flat or Deflated Tires (for improved grip on sandy terrains), Raising the temperature above the Curie point to convert a ferromagnetic substance to a paramagnetic substance, Employee Benefit Programs (flexibility in terms of options and contributions most suited to an individual) etc.

SYNONYMS: Transformation of Properties, Configuration, Parameter Change

ACB:

The Parameter Change principle refers to a concept where the value of a certain parameter or characteristic of a system or product is intentionally changed to achieve a desired effect. This principle involves manipulating key parameters to improve performance, overcome limitations, or find innovative solutions to problems. The essence of the Parameter Change principle lies in recognizing that altering specific parameters can lead to significant improvements or breakthroughs in a given system. By deliberately changing or adjusting certain factors, engineers and innovators can find ways to enhance functionality, efficiency, or overall performance. Recognizing the critical parameters or characteristics of a system that are relevant to the problem at hand. Deliberately changing the value or state of identified parameters to achieve a specific goal or address a particular issue. Evaluating the impact of parameter changes on the overall system and identifying how these alterations contribute to the desired outcome. Generating inventive solutions by considering alternative values, states, or combinations of parameters.

A:. Change the physical state of the sysetm

A. Change the physical state of the system refers to altering the physical characteristics or properties of a system to achieve a desired outcome or address a problem. This principle involves manipulating factors such as temperature, pressure, volume, or state of matter to optimize system performance or functionality.

Example: Phase Change Cooling in Electronics Thermal Management: In electronics thermal management, phase change cooling exemplifies the application of this principle to solve the problem of heat dissipation in electronic devices. As electronic components operate, they generate heat, which can degrade performance and lead to premature failure if not effectively managed. Phase change cooling systems utilize the principle of changing the physical state of a coolant to efficiently absorb and dissipate heat from electronic components. These systems typically employ a coolant fluid, such as a refrigerant or dielectric fluid, which undergoes a phase transition from liquid to vapor as it absorbs heat from the electronic components. During operation, the coolant fluid is circulated through a closed-loop system that includes heat exchangers and evaporators located in proximity to the electronic components. As the coolant absorbs heat from the components, it undergoes a phase change from liquid to vapor, effectively transferring thermal energy away from the components. Once the vaporized coolant reaches a condenser unit, it undergoes a phase change back to liquid as it releases heat to the surrounding environment or a separate cooling system. The liquid coolant is then recirculated back to the evaporator to repeat the cooling cycle. By changing the physical state of the coolant fluid from liquid to vapor and back to liquid, phase change cooling systems efficiently manage heat dissipation in electronic devices, maintaining optimal operating temperatures and prolonging component lifespan. This approach enhances the reliability and performance of electronic systems, particularly in applications where traditional air or liquid cooling methods may be insufficient.

B: Change the concentration or density (or consistency or intensity)

B: Change the concentration or density (or consistency or intensity) involves altering the concentration, density, consistency, or intensity of a substance or medium within a technical system to achieve a desired outcome or solve a problem. This principle relies on adjusting the composition or distribution of materials to optimize system performance or functionality.

Example: Inkjet Printing Technology: In inkjet printing technology, the principle of changing concentration or density is applied to control the deposition of ink onto a substrate, such as paper or film. Inkjet printers utilize microscopic nozzles to eject droplets of ink onto the printing surface, forming characters, images, or patterns. By modulating the concentration and density of ink droplets deposited on the substrate, inkjet printers can achieve varying levels of color intensity, shading, and detail in the printed output. The printer’s control system adjusts the frequency and volume of ink droplets ejected from the nozzles based on the desired image or text, as well as the properties of the printing substrate. For example, when printing high-resolution photographs, the printer may increase the density of ink droplets in areas requiring greater color saturation or detail, such as shadows or fine textures. Conversely, in areas of smooth gradients or lighter shades, the printer may reduce the concentration of ink droplets to avoid excessive saturation or bleeding. By changing the concentration or density of ink droplets during the printing process, inkjet printers can produce high-quality, accurately rendered images with precise color reproduction and fine detail. This application of the principle optimizes the printing process and enhances the overall quality of printed materials.

C: Change the degree of flexibility (shape, structure or phase specific dimensional properties)

C: Change the degree of flexibility (shape, structure, or phase-specific dimensional properties) involves altering the flexibility or rigidity of a system’s components, structures, or materials to adapt to varying conditions or requirements. This principle emphasizes adjusting the shape, structure, or dimensional properties of objects to optimize their functionality or performance.

Example: Shape-Memory Alloys in Biomedical Devices: Shape-memory alloys (SMAs) exemplify the application of the principle of changing the degree of flexibility in technical systems, particularly in biomedical devices. SMAs are a class of materials that exhibit the ability to revert to a predetermined shape or configuration when subjected to specific stimuli, such as temperature changes. In biomedical applications, SMAs are utilized in devices such as stents, orthodontic wires, and surgical instruments, where the ability to change shape or flexibility is advantageous. For example, in cardiovascular stents used to treat blocked arteries, SMAs can be engineered to exhibit a flexible, compressed state for insertion into the blood vessel. Once deployed at the treatment site, the stent is exposed to body temperature, causing it to undergo a phase transition and revert to its original expanded shape, thereby propping open the artery and restoring blood flow. By changing the degree of flexibility in response to external stimuli, SMAs enable the design of minimally invasive medical devices that can adapt to dynamic physiological conditions within the body. This application of the principle enhances the performance and effectiveness of biomedical devices while minimizing patient discomfort and improving clinical outcomes.

D: Change the object’s temperature and/or other physical properties such as volume, pressure, density, inductance, capacitance, viscosity, radiance etc.

D: Change the object’s temperature and/or other physical properties such as volume, pressure, density, inductance, capacitance, viscosity, radiance, etc. involves manipulating the temperature or other physical properties of an object to achieve a desired outcome or address a specific problem. This principle focuses on controlling various parameters that influence the behavior or characteristics of a system, enabling optimization of its performance or functionality.

Example: Thermal Expansion Compensators in Bridges: Thermal expansion compensators in bridges illustrate the application of the principle of changing physical properties to solve a problem. Bridges are subjected to temperature variations, which can cause expansion and contraction of structural elements, leading to stress buildup and potential damage over time. To address this challenge, engineers incorporate thermal expansion compensators into bridge designs. These compensators are typically installed at points where different sections of the bridge meet or where expansion joints are located. They are designed to accommodate changes in temperature-induced expansion and contraction without imposing excessive stress on the bridge structure. One common type of thermal expansion compensator is the expansion joint, which consists of flexible materials or mechanisms that allow the bridge components to move relative to each other in response to temperature changes. As the temperature increases, the bridge components expand, and the expansion joint compresses or extends to absorb the thermal expansion without compromising the structural integrity of the bridge. By changing the temperature and physical properties of the expansion joint materials, such as their coefficient of thermal expansion or elasticity, engineers can optimize the performance of the bridge under varying environmental conditions. This application of the principle ensures the longevity and safety of bridge structures by effectively managing the effects of temperature fluctuations on their components.

E: Change the operational effect or properties by varying the chemical compositions or properties – formulation, pH, solubility etc.

E: Change the operational effect or properties by varying the chemical compositions or properties – formulation, pH, solubility, etc. involves modifying the chemical composition or properties of a substance to alter its operational effects or properties. This principle emphasizes the manipulation of chemical factors to achieve specific objectives or address particular challenges within a technical system.

Example: pH Adjustment in Water Treatment: The process of pH adjustment in water treatment systems exemplifies the application of the principle of changing chemical compositions or properties to solve a problem. In water treatment facilities, it is essential to maintain the pH level of the water within a specified range to ensure its suitability for consumption, industrial use, or environmental discharge. One common method for pH adjustment involves the addition of chemical reagents to the water to modify its acidity or alkalinity. For example, if the pH of the water is too acidic (below the desired range), alkaline substances such as sodium hydroxide (NaOH) or calcium hydroxide (Ca(OH)2) may be added to raise the pH and neutralize the acidity. Conversely, if the pH is too alkaline (above the desired range), acidic substances such as sulfuric acid (H2SO4) or carbon dioxide (CO2) may be introduced to lower the pH and counteract the alkalinity. By varying the chemical compositions or properties of the additives used for pH adjustment, water treatment plants can effectively control the pH of the water to meet regulatory standards and specific operational requirements. This application of the principle ensures the quality and safety of treated water for various purposes, including drinking, industrial processes, and environmental conservation.

F: Change the order of occurence of actions or operations (introduce serial-position effect, Introduce peak-end effect)

F: Change the order of occurrence of actions or operations (introduce serial-position effect, introduce peak-end effect) involves rearranging the sequence in which actions or operations are performed to influence the overall outcome or perception of an experience. This principle emphasizes the impact of temporal sequencing on user perception, behavior, or system performance.

Example: User Interface Design for Automated Teller Machines (ATMs): In the design of user interfaces for automated teller machines (ATMs), the principle of changing the order of occurrence of actions is applied to enhance user experience and satisfaction. ATMs are used by millions of people worldwide for conducting various banking transactions, including cash withdrawals, balance inquiries, and fund transfers. To optimize the user experience, ATM interface designers leverage psychological principles such as the serial-position effect and the peak-end effect. The serial-position effect suggests that users tend to remember and prioritize information presented at the beginning (primacy effect) and end (recency effect) of a sequence, while the peak-end effect suggests that users’ overall perception of an experience is influenced by the most intense (peak) and final (end) moments. By strategically arranging the sequence of actions or operations in the ATM interface, designers can capitalize on these cognitive biases to improve user engagement and satisfaction. For example, the ATM interface may begin with a clear and user-friendly menu of transaction options (primacy effect), followed by prompts for user input and confirmation (peak), and conclude with a reassuring message confirming the completion of the transaction (end). By introducing the serial-position effect and peak-end effect into the design of ATM interfaces, financial institutions can create a more intuitive and user-friendly experience for customers, leading to increased usage and satisfaction with ATM services. This application of the principle enhances the overall effectiveness and usability of ATM systems in facilitating banking transactions.

G: Consider the full spectrum of properties, states of transition, interfaces, etc., as a set — not in isolation — for the transformation, parameterization, or configurations of the system. (eliminate essentialism).

G: Consider the full spectrum of properties, states of transition, interfaces, etc., as a set — not in isolation — for the transformation, parameterization, or configurations of the system (eliminate essentialism). involves adopting a holistic approach to system design by considering all relevant properties, states, and interfaces as interconnected elements rather than isolated components. This principle emphasizes the importance of understanding the complex interplay between different aspects of a system to achieve optimal performance, functionality, or configuration.

Example: Smart Home Automation System: In the design of a smart home automation system, the principle of considering the full spectrum of properties and states is applied to create a seamless and integrated user experience. A smart home system typically consists of various interconnected devices and sensors, such as thermostats, lighting controls, security cameras, and smart appliances, all of which interact to enhance comfort, convenience, and energy efficiency within the home. By eliminating essentialism and considering the full spectrum of properties and states, designers can develop a smart home system that dynamically adapts to changing environmental conditions, user preferences, and energy usage patterns. For example, instead of treating each smart device as an isolated component with predefined functionalities, the system can analyze data from multiple sensors and devices simultaneously to make intelligent decisions and adjustments in real-time. For instance, suppose a smart home automation system integrates temperature sensors, occupancy sensors, and smart thermostats to regulate heating and cooling throughout the home. By considering the full spectrum of properties, including temperature fluctuations, occupancy patterns, and energy consumption, the system can optimize heating and cooling schedules, adjust room temperatures based on user preferences and occupancy, and identify opportunities for energy savings. In this way, the smart home automation system leverages the principle of considering the full spectrum of properties to create a cohesive and adaptive environment that enhances comfort, convenience, and energy efficiency for occupants. This holistic approach to system design ensures that the various components and functionalities work together synergistically to achieve the desired outcomes and deliver a superior user experience.

High fuel consumption in a vehicle leading to reduced fuel efficiency. Fuel efficiency is influenced by factors such as aerodynamics. Change the shape or design of the vehicle to improve aerodynamics. Improved aerodynamics can reduce air resistance, leading to better fuel efficiency. Explore innovative vehicle designs, such as streamlined shapes or retractable features, to optimize aerodynamics and reduce fuel consumption. In this example, changing the parameter of vehicle aerodynamics directly impacts fuel efficiency. By intentionally modifying this parameter, engineers can devise innovative solutions to address the problem of high fuel consumption.

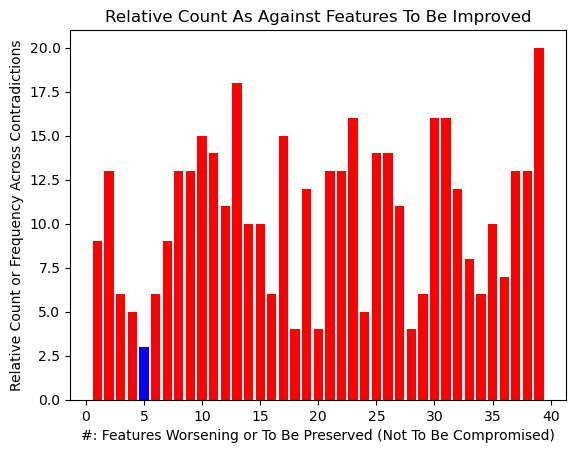

By deliberately changing specific parameters, the Parameter Change principle aims to resolve or mitigate these contradictions: (1) Improving the performance of a system may lead to increased resource consumption. Parameter change could involve optimizing certain parameters to enhance performance while minimizing resource usage. (2) Increasing the speed of a process or system may compromise its stability. Parameter change might involve adjusting relevant factors to achieve a balance between speed and stability. (3) Enhancing the strength of a structure may result in increased weight. Parameter change could involve modifying the structure’s design or materials to achieve a balance between strength and weight. (4) Improving the accuracy of a process may slow it down. Parameter change might involve finding a way to optimize the relevant parameters for both accuracy and speed.

(5) Increasing the complexity of a system may make it more difficult to operate or maintain. Parameter change could involve simplifying certain aspects without sacrificing overall system performance. (6) Enhancing product quality may lead to increased production costs. Parameter change might involve finding ways to improve quality without significantly escalating costs. (7) Adding safety features may restrict the functionality of a product or system. Parameter change could involve designing safety features that enhance functionality without compromising safety. (8) Increasing flexibility may result in decreased rigidity. Parameter change might involve optimizing certain parameters to achieve a balance between flexibility and rigidity. (9) Improving energy efficiency may sometimes lead to a reduction in overall system performance. Parameter change could involve optimizing energy-related parameters while maintaining or even enhancing performance.

Automotive Radiator: Adjusting the state of the coolant from liquid to gas in the radiator to facilitate heat exchange. Controlling the temperature of the coolant to optimize the cooling efficiency. Polymer Injection Molding Machine: Changing the polymer from a solid state to a molten state during the injection molding process. Adjusting the temperature of the molten polymer to optimize molding characteristics. Air Conditioning System: Altering the state of the refrigerant from gas to liquid and back to control temperature. Adjusting the temperature settings to achieve optimal cooling or heating. Metal Forging Process: Heating metal to a molten state and then forging it into a desired shape. Controlling the temperature of the metal to ensure proper forging. Chemical Reaction Vessel: Initiating or terminating chemical reactions that involve changes in state (solid to liquid, gas, etc.). Adjusting the temperature to optimize reaction rates. Water Treatment Plant: Treating water to change its state from contaminated to purified. Adjusting the concentration of chemicals used for water treatment to optimize purification. Flexible Manufacturing System (FMS): Adapting the flexibility of production lines to accommodate different product specifications. Transitioning between different production states based on demand. Plasma Cutting Machine: Converting electrical energy into plasma to cut through various materials. Controlling the temperature of the plasma for efficient cutting. Space Heating System: Transforming electrical energy into heat for space heating. Adjusting the temperature settings to achieve comfort and energy efficiency. Bioreactor in Biotechnology: Altering the state of the culture medium to support microbial growth (liquid to solid, gas production). Adjusting parameters like pH, pressure, and nutrient concentration to optimize bioprocesses.

Medical professionals consider various factors when deciding on the form of medication delivery for a patient. The choice between oral medications, tablets, injections, or other forms depends on the specific characteristics of the medication, the patient’s condition, and other individual factors. Here are some common forms of medication delivery and the factors influencing their choice: 1. Oral Medications (Tablets, capsules, liquids, or chewable tablets.) : Oral medications are often convenient and easy for patients to self-administer. Oral medications may enhance patient compliance as they are generally less invasive. The medication must be able to survive the digestive process and be absorbed through the gastrointestinal tract. 2. Injections: (Intramuscular (IM), subcutaneous (SC), or intravenous (IV) ): Injections can provide a quicker onset of action compared to oral medications. Some medications are unstable in the digestive tract and require injection. In emergency situations or critical conditions, injections may be preferred. 3. Topical Medications (Creams, ointments, patches, or gels: Localized Treatment: Topical medications are used for localized treatment, such as skin conditions or pain relief. Topical applications can minimize systemic side effects. 4. Inhalation Medications (Inhalers or nebulizers): Respiratory Conditions: Inhalation is often used for respiratory conditions like asthma or chronic obstructive pulmonary disease (COPD). Allows medication to be delivered directly to the lungs. 5. Suppositories (Rectal or vaginal suppositories.): Suppositories are used when medications need to bypass the digestive tract.

Some patients may have preferences or aversions to specific forms of medication. Stability, solubility, and bioavailability of the medication influence the chosen form. The urgency of treatment and the severity of the patient’s condition may dictate the speed of medication delivery. Patients with difficulty swallowing may be prescribed liquid medications or alternative forms. The nature and duration of the condition may influence the chosen form of medication. Ultimately, the decision on the best way to deliver medication is made through careful consideration of these factors, ensuring effective treatment while minimizing side effects and inconvenience to the patient.

The “Two Words” method is a creative thinking and problem-solving technique that involves expressing a situation, challenge, or concept in just two words. The “Two Words” method is adaptable and can be applied to various contexts, making it a versatile tool for creative problem-solving and brainstorming sessions. It is a concise and focused approach to distilling the essence of a problem or idea into a brief and impactful form. This method is often used in brainstorming sessions and creative exercises to prompt exploration and generate new perspectives.

The “Two Words” method typically works by reducing or condensing the problem statement or objective expressed using two words and then using it to expand or develop a mind map using brainstorming: Clearly define the topic, challenge, or concept you want to explore or address. This could be a problem to solve, a project to work on, or a creative idea to develop. Summarize the essence of the topic or challenge using only two words. These two words should capture the core or key aspects of the issue. Reflect on the chosen two words and consider how they relate to the broader context. Think about the associations, meanings, and potential solutions or directions implied by those two words. Use the two words as a springboard for idea generation. Explore different perspectives, potential solutions, or creative directions inspired by the concise representation of the topic. If in a group setting, individuals can share their chosen two words and collectively explore the diverse perspectives generated by the group.

Example: “Sustainable Transportation” or “Green Mobility”. This may prompt ideas related to eco-friendly transportation solutions, renewable energy, or environmentally conscious mobility options. Two words forces participants to distill complex topics into concise and focused expressions. It encourages creative thinking by presenting a challenge in a simplified form. It serves as a starting point for idea generation, prompting exploration based on the core essence of the topic. It facilitates efficient communication of ideas, making it easier for individuals to express and share their perspectives. It allows for diverse interpretations and perspectives, leading to a range of ideas and solutions.

Marking on bottles or thermometers to indicate levels is an example of the “Parameter Change” principle . This principle involves changing a parameter in a system to achieve a desired effect or function. In this case, the parameter being changed is the visual or physical representation of the liquid level on the bottle or the temperature level on the thermometer. The marking on the bottle or thermometer allows users to easily and quickly assess the level of liquid or temperature without the need for additional measurements or instruments. This visual representation simplifies the monitoring process and enhances the usability of the product, aligning with the idea of changing a parameter (appearance or visibility) to convey important information to the user. The marking on bottles or thermometers to indicate levels can also be considered an example of feedback. Feedback systems involve providing information about the system’s output or performance back to the input, allowing for monitoring and adjustment. The level of liquid in the bottle or the temperature on the thermometer. The markings or indicators that visually represent the level. Users receive feedback through the visual cues provided by the markings, allowing them to make informed decisions or take appropriate actions based on the current state of the system. This feedback loop is crucial for effective use and control of the product.

The software-based features contribute to the versatility and adaptability of modern computer mice, allowing users to tailor their mouse’s behavior and performance to suit their specific needs and preferences. It’s advisable to check the latest product specifications and reviews for the most up-to-date information on mouse features and functionalities. Many modern mice come with programmable buttons that can be customized using software. Users can assign specific functions, macros, or commands to these buttons through the mouse’s software. This allows for personalized shortcuts and improved efficiency in tasks. Users can customize the DPI settings through software, enabling them to switch between high and low sensitivity levels. This is particularly useful for tasks like gaming or precision design work. Software interprets specific mouse movements or gestures, allowing users to perform actions like scrolling, zooming, or navigating between applications without using traditional buttons. The software allows users to calibrate the mouse to the specific surface it’s on, optimizing tracking accuracy and performance. Software enables users to choose the color, intensity, and even dynamic lighting effects, creating a personalized visual experience. Users can create and switch between profiles with unique button assignments, DPI settings, and other configurations using the mouse’s software. This is handy for different tasks or gaming scenarios. The mouse software may provide information on battery levels and offer power-saving settings to extend battery life. Some mice may also support quick charging features. Keeping the mouse’s firmware up-to-date for performance and security improvements. Manufacturers release firmware updates that users can apply through the mouse’s software, ensuring compatibility with new features and addressing potential issues.

Essentialism bias refers to the tendency to categorize systems or people, objects, or concepts based on their perceived inherent or essential qualities, rather than considering the full range of characteristics or variability within that category. It involves oversimplifying complex entities by attributing fixed, immutable properties to them, which may not accurately reflect their true nature or diversity. Consider a water filtration system. In this system, the essential function is to remove impurities from water to make it safe for drinking. The essential components may include filters, membranes, pumps, and purification chemicals. However, an essentialism bias might lead designers to focus solely on these core components while overlooking other important factors such as maintenance requirements, energy efficiency, durability, or user-friendliness. To address this bias, the principle of Parameter Changes could be applied by broadening the scope of consideration. For example: Parameter Change #1: Introduce self-cleaning mechanisms to reduce maintenance needs. Parameter Change #2: Optimize pump efficiency to minimize energy consumption. Parameter Change #3: Use durable materials to increase the system’s lifespan. Parameter Change #4: Design intuitive controls for easy operation by users. By expanding the focus beyond just the essential components, the water filtration system can be optimized for overall performance, reliability, and user satisfaction, rather than solely focusing on removing impurities. In brief, essentialism bias can lead to stereotyping, prejudice, or discrimination by overlooking the nuances and variability within social groups, objects, or concepts. It can hinder critical thinking and understanding by promoting simplistic and rigid categorizations based on perceived essential characteristics and hence needs to be eliminated whenthinking inventively.

The order of occurence of event or operations has an impact on its recall value. The first and last items in a list are often easier to remember, and this phenomenon is known as the primacy and recency effects, respectively. However, the serial recall effect specifically focuses on the tendency for individuals to remember items in the order they were presented or sought to occur, regardless of whether they are from the beginning, middle, or end of the list. In other words, even though people may remember the first and last items more easily due to primacy and recency effects, they will still tend to recall all items in the order they were originally presented (first to last). This sequential recall pattern is what characterizes the serial recall effect. For instance, if you are given a list of words to remember—let’s say “cat, dog, bird, fish, rabbit”—you are more likely to recall staring from “cat” and “dog” (the first and second items) more accurately compared to botton up from “rabbit” and “fish” (the fifth and fourth). This effect highlights the importance of the order of presentation in influencing memory recall. In the context of technical systems, this phenomenon can impact the design of flow or sequences or interfaces, menus, or any sequential presentation of information. Designers must reconsider or change the order in which information is to be presented to optimize user memory retention of important or relevant items and facilitate efficient recall.

The peak-end rule is a cognitive bias that suggests people tend to judge past experiences, particularly those with emotional components, based on the peak (most intense) moment and the end (final) moment, rather than considering the experience in its entirety. According to this bias, the peak emotional intensity and the way an experience concludes heavily influence how it is remembered and evaluated. Here’s a simplified example to illustrate the peak-end rule: Imagine you go on a vacation to a tropical island. During your trip, you experience various activities, such as snorkeling, hiking, and relaxing on the beach. On the last day of your vacation, you encounter a sudden rainstorm while hiking, which dampens your mood. Despite enjoying the majority of your trip, the memory of the rainstorm at the end of the vacation becomes a significant factor in how you later evaluate the entire experience. In this example, the peak emotional moment (the rainstorm) and the end of the experience (the conclusion of the vacation) disproportionately influence your overall memory and assessment of the trip, according to the peak-end rule. When designing software interfaces or digital products, designers can leverage the peak-end rule to prioritize memorable and positive experiences during critical moments of user interaction. For example, ensuring that the peak performance of an application (such as fast loading times or smooth transitions) occurs during key user interactions can leave a lasting positive impression.

When designing customer service interactions or support systems, companies can utilize the peak-end rule to ensure that the resolution of customer issues leaves a positive final impression. This might involve prioritizing efficient problem-solving and ensuring that customer interactions end on a satisfactory note, even if issues were encountered earlier in the process. In the context of system performance optimization, developers may focus efforts on improving the peak performance moments of a system to enhance user satisfaction. For instance, optimizing response times for critical system operations or ensuring that resource-intensive tasks complete smoothly can positively influence user perceptions of overall system performance. Understanding and leveraging the peak-end rule can help designers and developers create more satisfying user experiences, optimize system performance, and manage user perceptions effectively throughout the interaction with the system.

The placebo effect refers to the phenomenon where a patient experiences improvement in their condition after receiving a treatment that has no therapeutic effect on its own. This improvement is attributed to the patient’s belief in the treatment’s effectiveness rather than any physiological or biochemical properties of the treatment itself. The placebo effect is widely recognized in medical research and clinical practice, particularly in studies evaluating the efficacy of new drugs or medical interventions. In these studies, participants may be given a placebo (such as a sugar pill or saline solution) instead of the actual treatment being tested. Despite receiving an inert substance, some participants may experience symptom relief or other improvements solely because they believe they are receiving a beneficial treatment. The placebo effect can manifest in various ways, including pain reduction, symptom alleviation, and subjective improvements in overall well-being. The mechanisms underlying the placebo effect are complex and not fully understood, but they likely involve psychological factors such as expectancy, conditioning, and the patient-provider relationship. In clinical practice, the placebo effect highlights the importance of considering patients’ beliefs, expectations, and psychological well-being in addition to providing evidence-based treatments. It also underscores the need for rigorous study design and careful interpretation of research findings to distinguish genuine treatment effects from placebo responses.

The placebo effect, while primarily a phenomenon observed in medical contexts, can also have implications for designing technical systems, particularly those that involve human interaction or perception. Here are a few ways in which the placebo effect can influence the design of technical systems: User Experience (UX) Design: In systems where user perception plays a significant role, such as user interfaces, virtual reality environments, or gaming systems, designers may leverage placebo-like effects to enhance user experience. For example, incorporating subtle visual or auditory cues that suggest system responsiveness or effectiveness can influence users’ perceptions of the system’s performance, even if there are no tangible improvements in functionality. Feedback and Encouragement: In systems designed to support behavior change or skill acquisition, providing feedback and encouragement can have placebo-like effects on users’ motivation and performance. Designers can use techniques such as gamification, progress tracking, and positive reinforcement to create a sense of achievement and efficacy, thereby motivating users to engage with the system more effectively. Perception of Quality: In consumer products or services, the placebo effect can influence users’ perceptions of quality, reliability, and value. Designers may strategically incorporate elements that signal quality or prestige, such as sleek design, premium materials, or branding cues, to evoke positive associations and enhance user satisfaction. Trust and Confidence: The placebo effect can also influence users’ trust and confidence in technical systems, particularly those that involve autonomous or AI-driven decision-making. Designers can employ transparency, explainability, and human-centered design principles to instill trust and confidence in users, even if the system’s underlying mechanisms are complex or opaque. Psychological Well-being: In systems designed to support mental health or well-being, the placebo effect can play a role in promoting positive outcomes. Designers may incorporate elements that evoke feelings of comfort, reassurance, or empathy to enhance users’ psychological well-being and foster a sense of support and connection. Overall, while the placebo effect may not have direct applications in the technical functionality of systems, it can inform design decisions related to user experience, perception, motivation, and trust, ultimately contributing to the overall effectiveness and acceptance of the technology by users.

1: Mass of the moving object: [’12: Shape’, ’13: Stability of the object’, ’15: Action time of the moving object’, ’19: Energy consumption of the moving object’, ’23: Material loss’, ’24: Information loss’, ’25: Time loss’, ’28: Accuracy of measurement’, ’29: Accuracy of manufacturing’, ’31: Harmful internal factors’, ’33: Convenience of use’, ’38: Level of automation’, ’39: Productivity’]

2: Mass of the non-moving object: [‘4: Length of the non-moving object’, ‘6: Area of the non-moving object’, ‘8: Volume of the non-moving object’, ’10: Force’, ’18: Brightness, Visibility’, ’24: Information loss’, ’25: Time loss’, ’29: Accuracy of manufacturing’, ’31: Harmful internal factors’, ’38: Level of automation’, ’39: Productivity’]

3: Length of the moving object: [‘7: Volume of the moving object’, ’11: Tension, Pressure’, ’14: Strength’, ’19: Energy consumption of the moving object’, ’21: Power’, ’22: Energy loss’, ’26: Amount of substance’, ’33: Convenience of use’, ’37: Complexity of control and measurement’]

4: Length of the non-moving object: [‘2: Mass of the non-moving object’, ‘8: Volume of the non-moving object’, ’11: Tension, Pressure’, ’13: Stability of the object’, ’16: Action time of the non-moving object’, ’17:Temperature’, ’23: Material loss’, ’35: Adaptability’]

5: Area of the moving object: [’10: Force’, ’23: Material loss’]

6: Area of the non-moving object: [’10: Force’, ’17:Temperature’, ’25: Time loss’, ’27: Reliability’, ’30: Harmful external factors’, ’37: Complexity of control and measurement’]

7: Volume of the moving object: [‘3: Length of the moving object’, ’10: Force’, ’11: Tension, Pressure’, ’15: Action time of the moving object’, ’19: Energy consumption of the moving object’, ’21: Power’, ’30: Harmful external factors’, ’38: Level of automation’]

8: Volume of the non-moving object: [‘2: Mass of the non-moving object’, ‘4: Length of the non-moving object’, ’11: Tension, Pressure’, ’12: Shape’, ’13: Stability of the object’, ’16: Action time of the non-moving object’, ’17:Temperature’, ’23: Material loss’, ’25: Time loss’, ’26: Amount of substance’, ’27: Reliability’, ’29: Accuracy of manufacturing’, ’31: Harmful internal factors’, ’32: Convenience of manufacturing’, ’39: Productivity’]

9: Speed: [’12: Shape’, ’15: Action time of the moving object’, ’19: Energy consumption of the moving object’, ’21: Power’, ’22: Energy loss’, ’27: Reliability’, ’30: Harmful external factors’, ’31: Harmful internal factors’, ’32: Convenience of manufacturing’]

10: Force: [’12: Shape’, ’13: Stability of the object’, ’14: Strength’, ’17:Temperature’, ’21: Power’, ’23: Material loss’, ’27: Reliability’, ’28: Accuracy of measurement’, ’30: Harmful external factors’, ’36: Complexity of the structure’, ’38: Level of automation’, ’39: Productivity’]

11: Tension, Pressure: [‘3: Length of the moving object’, ‘4: Length of the non-moving object’, ‘7: Volume of the moving object’, ‘8: Volume of the non-moving object’, ‘9: Speed’, ’10: Force’, ’12: Shape’, ’13: Stability of the object’, ’17:Temperature’, ’21: Power’, ’27: Reliability’, ’29: Accuracy of manufacturing’, ’32: Convenience of manufacturing’, ’35: Adaptability’, ’36: Complexity of the structure’, ’38: Level of automation’, ’39: Productivity’]

12: Shape: [‘8: Volume of the non-moving object’, ‘9: Speed’, ’10: Force’, ’23: Material loss’, ’30: Harmful external factors’, ’31: Harmful internal factors’]

13: Stability of the object: [‘1: Mass of the moving object’, ‘8: Volume of the non-moving object’, ’10: Force’, ’11: Tension, Pressure’, ’15: Action time of the moving object’, ’16: Action time of the non-moving object’, ’17:Temperature’, ’21: Power’, ’25: Time loss’, ’26: Amount of substance’, ’30: Harmful external factors’, ’31: Harmful internal factors’, ’32: Convenience of manufacturing’, ’33: Convenience of use’, ’34: Convenience of repair’, ’35: Adaptability’, ’36: Complexity of the structure’, ’37: Complexity of control and measurement’, ’38: Level of automation’, ’39: Productivity’]

14: Strength: [‘3: Length of the moving object’, ’12: Shape’, ’13: Stability of the object’, ’18: Brightness, Visibility’, ’19: Energy consumption of the moving object’, ’20: Energy consumption of the non-moving object’, ’21: Power’, ’22: Energy loss’, ’23: Material loss’, ’30: Harmful external factors’, ’31: Harmful internal factors’, ’39: Productivity’]

15: Action time of the moving object: [‘9: Speed’, ’13: Stability of the object’, ’17:Temperature’, ’18: Brightness, Visibility’, ’19: Energy consumption of the moving object’, ’21: Power’, ’26: Amount of substance’, ’35: Adaptability’, ’37: Complexity of control and measurement’, ’39: Productivity’]

16: Action time of the non-moving object: [‘4: Length of the non-moving object’, ‘8: Volume of the non-moving object’, ’13: Stability of the object’, ’26: Amount of substance’, ’32: Convenience of manufacturing’, ’37: Complexity of control and measurement’]

17:Temperature: [‘2: Mass of the non-moving object’, ‘5: Area of the moving object’, ‘6: Area of the non-moving object’, ‘8: Volume of the non-moving object’, ’10: Force’, ’11: Tension, Pressure’, ’13: Stability of the object’, ’22: Energy loss’, ’25: Time loss’, ’27: Reliability’, ’30: Harmful external factors’, ’31: Harmful internal factors’, ’37: Complexity of control and measurement’, ’39: Productivity’]

18: Brightness, Visibility: [‘2: Mass of the non-moving object’, ’14: Strength’, ’17:Temperature’, ’20: Energy consumption of the non-moving object’, ’31: Harmful internal factors’, ’32: Convenience of manufacturing’]

19: Energy consumption of the moving object: [‘7: Volume of the moving object’, ‘9: Speed’, ’14: Strength’, ’15: Action time of the moving object’, ’23: Material loss’, ’25: Time loss’, ’30: Harmful external factors’, ’31: Harmful internal factors’, ’33: Convenience of use’, ’37: Complexity of control and measurement’, ’39: Productivity’]

20: Energy consumption of the non-moving object: [’14: Strength’, ’18: Brightness, Visibility’, ’26: Amount of substance’, ’37: Complexity of control and measurement’]

21: Power: [‘3: Length of the moving object’, ‘7: Volume of the moving object’, ‘9: Speed’, ’10: Force’, ’11: Tension, Pressure’, ’13: Stability of the object’, ’15: Action time of the moving object’, ’22: Energy loss’, ’25: Time loss’, ’31: Harmful internal factors’, ’33: Convenience of use’, ’34: Convenience of repair’, ’37: Complexity of control and measurement’, ’39: Productivity’]

22: Energy loss: [‘9: Speed’, ’23: Material loss’, ’27: Reliability’, ’30: Harmful external factors’, ’31: Harmful internal factors’, ’33: Convenience of use’, ’37: Complexity of control and measurement’, ’39: Productivity’]

23: Material loss: [‘1: Mass of the moving object’, ‘2: Mass of the non-moving object’, ‘5: Area of the moving object’, ’12: Shape’, ’14: Strength’, ’19: Energy consumption of the moving object’, ’22: Energy loss’, ’25: Time loss’, ’27: Reliability’, ’29: Accuracy of manufacturing’, ’34: Convenience of repair’, ’36: Complexity of the structure’, ’37: Complexity of control and measurement’, ’38: Level of automation’, ’39: Productivity’]

24: Information loss: [‘1: Mass of the moving object’, ‘2: Mass of the non-moving object’, ’26: Amount of substance’, ’37: Complexity of control and measurement’, ’38: Level of automation’]

25: Time loss: [‘1: Mass of the moving object’, ‘6: Area of the non-moving object’, ‘8: Volume of the non-moving object’, ’13: Stability of the object’, ’17:Temperature’, ’19: Energy consumption of the moving object’, ’21: Power’, ’23: Material loss’, ’26: Amount of substance’, ’30: Harmful external factors’, ’31: Harmful internal factors’, ’32: Convenience of manufacturing’, ’35: Adaptability’, ’38: Level of automation’]

26: Amount of substance: [‘1: Mass of the moving object’, ‘2: Mass of the non-moving object’, ‘3: Length of the moving object’, ‘9: Speed’, ’10: Force’, ’12: Shape’, ’14: Strength’, ’15: Action time of the moving object’, ’16: Action time of the non-moving object’, ’20: Energy consumption of the non-moving object’, ’21: Power’, ’24: Information loss’, ’25: Time loss’, ’30: Harmful external factors’, ’31: Harmful internal factors’, ’32: Convenience of manufacturing’, ’33: Convenience of use’, ’38: Level of automation’]

27: Reliability: [‘6: Area of the non-moving object’, ‘8: Volume of the non-moving object’, ‘9: Speed’, ’11: Tension, Pressure’, ’12: Shape’, ’15: Action time of the moving object’, ’17:Temperature’, ’22: Energy loss’, ’23: Material loss’, ’30: Harmful external factors’, ’31: Harmful internal factors’, ’35: Adaptability’, ’36: Complexity of the structure’, ’39: Productivity’]

128: Accuracy of measurement: [‘1: Mass of the moving object’, ‘2: Mass of the non-moving object’, ’13: Stability of the object’, ’32: Convenience of manufacturing’, ’35: Adaptability’, ’36: Complexity of the structure’]

29: Accuracy of manufacturing: [‘2: Mass of the non-moving object’, ‘8: Volume of the non-moving object’, ’11: Tension, Pressure’, ’23: Material loss’, ’33: Convenience of use’]

30: Harmful external factors: [‘6: Area of the non-moving object’, ‘7: Volume of the moving object’, ‘9: Speed’, ’10: Force’, ’12: Shape’, ’13: Stability of the object’, ’14: Strength’, ’17:Temperature’, ’22: Energy loss’, ’25: Time loss’, ’26: Amount of substance’, ’32: Convenience of manufacturing’, ’34: Convenience of repair’, ’35: Adaptability’, ’39: Productivity’]

31: Harmful internal factors: [‘2: Mass of the non-moving object’, ‘8: Volume of the non-moving object’, ‘9: Speed’, ’10: Force’, ’12: Shape’, ’13: Stability of the object’, ’14: Strength’, ’17:Temperature’, ’19: Energy consumption of the moving object’, ’21: Power’, ’22: Energy loss’, ’39: Productivity’]

32: Convenience of manufacturing: [‘8: Volume of the non-moving object’, ‘9: Speed’, ’10: Force’, ’11: Tension, Pressure’, ’16: Action time of the non-moving object’, ’22: Energy loss’, ’25: Time loss’, ’26: Amount of substance’, ’28: Accuracy of measurement’, ’34: Convenience of repair’, ’39: Productivity’]

33: Convenience of use: [‘7: Volume of the moving object’, ’10: Force’, ’13: Stability of the object’, ’21: Power’, ’26: Amount of substance’, ’29: Accuracy of manufacturing’]

34: Convenience of repair: [‘1: Mass of the moving object’, ‘2: Mass of the non-moving object’, ‘7: Volume of the moving object’, ’13: Stability of the object’, ’23: Material loss’, ’30: Harmful external factors’, ’32: Convenience of manufacturing’, ’36: Complexity of the structure’, ’38: Level of automation’]

35: Adaptability: [‘3: Length of the moving object’, ‘4: Length of the non-moving object’, ‘5: Area of the moving object’, ‘7: Volume of the moving object’, ‘9: Speed’, ’11: Tension, Pressure’, ’13: Stability of the object’, ’14: Strength’, ’15: Action time of the moving object’, ’17:Temperature’, ’19: Energy consumption of the moving object’, ’25: Time loss’, ’26: Amount of substance’, ’27: Reliability’, ’28: Accuracy of measurement’, ’30: Harmful external factors’, ’38: Level of automation’, ’39: Productivity’]

36: Complexity of the structure: [‘2: Mass of the non-moving object’, ’11: Tension, Pressure’, ’22: Energy loss’, ’23: Material loss’, ’27: Reliability’]

37: Complexity of control and measurement: [‘9: Speed’, ’11: Tension, Pressure’, ’16: Action time of the non-moving object’, ’17:Temperature’, ’19: Energy consumption of the moving object’, ’20: Energy consumption of the non-moving object’, ’22: Energy loss’, ’24: Information loss’, ’39: Productivity’]

38: Level of automation: [‘1: Mass of the moving object’, ‘2: Mass of the non-moving object’, ‘7: Volume of the moving object’, ’10: Force’, ’11: Tension, Pressure’, ’23: Material loss’, ’24: Information loss’, ’25: Time loss’, ’26: Amount of substance’, ’34: Convenience of repair’, ’35: Adaptability’, ’39: Productivity’]

39: Productivity: [‘1: Mass of the moving object’, ‘6: Area of the non-moving object’, ‘8: Volume of the non-moving object’, ’13: Stability of the object’, ’15: Action time of the moving object’, ’17:Temperature’, ’19: Energy consumption of the moving object’, ’21: Power’, ’22: Energy loss’, ’23: Material loss’, ’26: Amount of substance’, ’27: Reliability’, ’30: Harmful external factors’, ’31: Harmful internal factors’, ’32: Convenience of manufacturing’, ’35: Adaptability’, ’37: Complexity of control and measurement’, ’38: Level of automation’]

1/12 1/13 1/15 1/19 1/23 1/24 1/25 1/28 1/29 1/31 1/33 1/38 1/39 2/4 2/6 2/8 2/10 2/18 2/24 2/25 2/29 2/31 2/38 2/39 3/7 3/11 3/14 3/19 3/21 3/22 3/26 3/33 3/37 4/2 4/8 4/11 4/13 4/16 4/17 4/23 4/35 5/10 5/23 6/10 6/17 6/25 6/27 6/30 6/37 7/3 7/10 7/11 7/15 7/19 7/21 7/30 7/38 8/2 8/4 8/11 8/12 8/13 8/16 8/17 8/23 8/25 8/26 8/27 8/29 8/31 8/32 8/39 9/12 9/15 9/19 9/21 9/22 9/27 9/30 9/31 9/32 10/12 10/13 10/14 10/17 10/21 10/23 10/27 10/28 10/30 10/36 10/38 10/39 11/3 11/4 11/7 11/8 11/9 11/10 11/12 11/13 11/17 11/21 11/27 11/29 11/32 11/35 11/36 11/38 11/39 12/8 12/9 12/10 12/23 12/30 12/31 13/1 13/8 13/10 13/11 13/15 13/16 13/17 13/21 13/25 13/26 13/30 13/31 13/32 13/33 13/34 13/35 13/36 13/37 13/38 13/39 14/3 14/12 14/13 14/18 14/19 14/20 14/21 14/22 14/23 14/30 14/31 14/39 15/9 15/13 15/17 15/18 15/19 15/21 15/26 15/35 15/37 15/39 16/4 16/8 16/13 16/26 16/32 16/37 17/2 17/5 17/6 17/8 17/10 17/11 17/13 17/22 17/25 17/27 17/30 17/31 17/37 17/39 18/2 18/14 18/17 18/20 18/31 18/32 19/7 19/9 19/14 19/15 19/23 19/25 19/30 19/31 19/33 19/37 19/39 20/14 20/18 20/26 20/37 21/3 21/7 21/9 21/10 21/11 21/13 21/15 21/22 21/25 21/31 21/33 21/34 21/37 21/39 22/9 22/23 22/27 22/30 22/31 22/33 22/37 22/39 23/1 23/2 23/5 23/12 23/14 23/19 23/22 23/25 23/27 23/29 23/34 23/36 23/37 23/38 23/39 24/1 24/2 24/26 24/37 24/38 25/1 25/6 25/8 25/13 25/17 25/19 25/21 25/23 25/26 25/30 25/31 25/32 25/35 25/38 26/1 26/2 26/3 26/9 26/10 26/12 26/14 26/15 26/16 26/20 26/21 26/24 26/25 26/30 26/31 26/32 26/33 26/38 27/6 27/8 27/9 27/11 27/12 27/15 27/17 27/22 27/23 27/30 27/31 27/35 27/36 27/39 28/1 28/2 28/13 28/32 28/35 28/36 29/2 29/8 29/11 29/23 29/33 30/6 30/7 30/9 30/10 30/12 30/13 30/14 30/17 30/22 30/25 30/26 30/32 30/34 30/35 30/39 31/2 31/8 31/9 31/10 31/12 31/13 31/14 31/17 31/19 31/21 31/22 31/39 32/8 32/9 32/10 32/11 32/16 32/22 32/25 32/26 32/28 32/34 32/39 33/7 33/10 33/13 33/21 33/26 33/29 34/1 34/2 34/7 34/13 34/23 34/30 34/32 34/36 34/38 35/3 35/4 35/5 35/7 35/9 35/11 35/13 35/14 35/15 35/17 35/19 35/25 35/26 35/27 35/28 35/30 35/38 35/39 36/2 36/11 36/22 36/23 36/27 37/9 37/11 37/16 37/17 37/19 37/20 37/22 37/24 37/39 38/1 38/2 38/7 38/10 38/11 38/23 38/24 38/25 38/26 38/34 38/35 38/39 39/1 39/6 39/8 39/13 39/15 39/17 39/19 39/21 39/22 39/23 39/26 39/27 39/30 39/31 39/32 39/35 39/37 39/38

EXAMPLE: Various resolution types in cameras provide flexibility to users, enabling them to choose the right tool for their specific needs and preferences. The resolution of a camera is determined by the number of pixels it can capture and is commonly measured in megapixels. Variations in pixel density among cameras offer photographers flexibility to choose a camera that best suits their specific needs and preferences. Higher pixel density is beneficial for applications requiring detailed images, while lower pixel density may suffice for scenarios where file size, low-light performance, or lens affordability are more critical considerations. It’s important for users to understand their specific requirements and consider how pixel density aligns with those needs when selecting a camera.

Contradiction (24/26) : High-resolution cameras are ideal for capturing intricate details in images, making them suitable for professional photography, landscape photography, and applications where fine details matter. But it takes more memory for storage as the pixel density increases. It is not always that one would need high resoluution videos or images. Cameras with higher pixel density produce larger image files. While this allows for more detailed images, it also requires more storage space. Cameras with lower pixel density produce smaller image files, which can be advantageous for users with limited storage capacity or those who prioritize faster file transfer and processing.

Solution: Some cameras are designed for specific applications, such as scientific imaging, surveillance, or capturing extremely high-resolution images for detailed analysis. Cameras with ultra-high resolutions, including gigapixel cameras, are used for creating panoramic images with exceptional detail, often used in fields like architecture and city planning. Low-resolution cameras produce smaller image files, making them suitable for users with limited storage capacity or those who prioritize faster file transfer and sharing. Low-resolution cameras are often found in smartphones and point-and-shoot cameras, making them convenient for everyday snapshots and casual photography. Variations in pixel density among cameras offer photographers flexibility to choose a camera that best suits their specific needs and preferences. Higher pixel density is beneficial for applications requiring detailed images, while lower pixel density may suffice for scenarios where file size, low-light performance, or lens affordability are more critical considerations.

Users can choose to downsize images for specific applications, balancing the trade-off between file size and image quality. Downsizing is common when sharing images online, as it reduces the file size for faster uploads and easier sharing. In case, changing pixel density is not a feature that users can use to control as in most standard cameras. They can indirectly influence the effective pixel density in their photographs through practices such as cropping and downsizing images using software during the post-processing stage.