26: COPYING: (A) Use a simplified, simulated, and inexpensive copy or model or replica of an object (or system) in place of a complex, fragile, expensive, inconvenient to operate original object (or system), (B) Use an optical image or simulation or reflection or projections instead of an object (or system) in original, (C) use an infrared or ultraviolet copies instead of using optical images of an object (or system)

EXAMPLE: Imitation Jewelry, Paper Models, CAD-CAM, Prototypes, Dummies in Crash Testing, Cadavers or Simulated Patients, Computer Simulation, Flight Simulators, Virtual Reality, Audio-Video Online Tutorials versus In-person or Interactive Seminars or Education, Image Snapshots (for counting, detection, or analysis etc), Measuring speed of birds using video, Sonograms, Space Surveillance, Data Transfer (Infrared), Infra-red guns to measure speed instead of movie/video, Scarecrow, Intruder Alarm Systems (simulated sounds or messages), Fire Drills, Mannequin, Moot Court, Mock Parliament, Film Sets/Studio, Imitation Jewellery 1)Imitation Jewelry [E1 IP 26.1].

SYNONYMS:

ACB:

“Copying” refers to the idea of replicating a mechanism or principle that already exists in a different object or system. At an abstract level, it involves adopting successful solutions from one domain and applying them to another to solve a similar problem. This principle is based on the notion that solutions proven effective in one context can be valuable when adapted to address analogous issues in another context. It promotes knowledge transfer, innovation, and the efficient application of proven concepts to address analogous challenges. Identify solutions or mechanisms that have proven effective in one domain. Apply these successful solutions to analogous problems in a different domain, leveraging their known efficiency. Recognize that knowledge gained in one field can be valuable in addressing challenges in another field. Transfer insights, methodologies, or solutions from one domain to another, fostering innovation through the adaptation of proven concepts.

Understand that successful concepts or mechanisms in one area can be borrowed and modified for application elsewhere. Identify concepts or solutions in one field and modify them to suit the requirements of a different field, facilitating problem-solving. Observing successful solutions in nature (biomimicry). Identify efficient structures, patterns, or processes in the natural world and replicate them in human-made designs for improved functionality. Replicating successful manufacturing processes from one industry to another. Transfer advanced manufacturing techniques or processes from one industry to another, improving efficiency and product quality.

Adopting successful medical treatments or procedures. Apply effective medical treatments developed for one condition to address similar issues or adapt successful surgical techniques for use in different medical contexts. Applying successful technologies from other industries to space exploration. Transfer technologies developed for industries like telecommunications or robotics to enhance capabilities in space exploration. Replicating successful teaching methods. Apply effective teaching strategies proven in one educational setting to improve learning outcomes in different educational contexts. The “Copying” principle encourages creative problem-solving by recognizing that solutions proven successful in one domain can be valuable resources when adapted for use in another domain.

The “Copying” principle facilitates the resolution of contradictions by leveraging successful solutions from one domain and applying them to address similar challenges in another. It encourages businesses and technical fields to learn from proven practices, fostering innovation and efficiency. So e of the business contradictions may be such as balancing the need for efficient supply chain processes with minimal disruptions. Adopting successful supply chain strategies used by companies in a different industry to improve efficiency and reduce disruptions instead of inventing. Enhancing customer relations while managing costs. Implementing CRM practices proven effective in one business sector to build and maintain customer relationships in a different industry. Maximizing employee productivity while ensuring employee well-being. Emulating successful employee well-being programs from other companies to create a balance between productivity and employee satisfaction. Accelerating product development without compromising quality. Adopting agile development methodologies or innovative product design practices from successful companies in unrelated industries.

Some of the technical contradictions that could be resolved using this principle include optimizing energy consumption during manufacturing processes without sacrificing productivity. pplying energy-efficient technologies and practices from other manufacturing sectors to improve efficiency in a specific industry. Choosing materials that are both durable and cost-effective. Replicating material selection strategies proven effective in one application to address similar durability challenges in another context. Enhancing data security while maintaining system usability. Implementing data security measures and encryption techniques used in one industry’s IT systems to strengthen security in another industry. Streamlining logistics operations while minimizing transportation costs. Adopting successful logistics and transportation strategies employed by companies in unrelated sectors to optimize operations. Ensuring high-quality products without slowing down the manufacturing process. Applying quality control methodologies and techniques from successful manufacturing sectors to maintain product quality in a different industry.

The type of museum where the physical space is adaptable and events or exhibits are projected onto walls, is often known as a “Projection Mapping Museum” or a “Digital Art Museum.” One well-known example is teamLab Borderless in Tokyo, Japan, which features digital art exhibits through projection mapping. The museum can transform its appearance instantly by changing the projected content, providing a dynamic and ever-changing experience. Projection mapping creates immersive and interactive experiences for visitors, blurring the boundaries between the physical and digital worlds. The museum can save costs on physical exhibits and renovations, as the digital content can be updated without significant structural changes. The space can be used for a variety of events and themes, catering to diverse audiences and interests. Digital exhibits often encourage visitor participation, fostering a more engaging and memorable experience.

Projection mapping allows a small physical space to host a wide range of digital exhibits, addressing the contradiction between limited space and the desire for diverse content. Traditional museums may struggle to provide dynamic and changing experiences. Projection mapping addresses this by allowing for instantaneous transformations and updates. Traditional museums may require significant renovations to change exhibits. Projection mapping provides flexibility without the need for costly physical alterations. Projection mapping allows museums to offer interactive experiences without risking damage to physical artifacts, addressing the contradiction between preservation and interactivity. Projection mapping museums often appeal to a younger, tech-savvy audience, providing a solution to the challenge of attracting a more contemporary demographic while maintaining relevance. Overall, projection mapping museums offer a paradigm shift in the way cultural institutions approach exhibitions, providing a harmonious blend of digital technology and artistic expression while addressing traditional museum-related contradictions.

The picture superiority effect is a phenomenon in cognitive psychology that refers to the tendency for humans to remember images better than words. In other words, people are more likely to recall information presented in the form of pictures or images compared to information presented in the form of words or text. Research suggests that this effect occurs because our brains are highly adept at processing visual information. Visual stimuli are often processed more efficiently and quickly than verbal stimuli, leading to better encoding and retention of information presented visually. Additionally, images are often more distinctive and memorable compared to words, which can further enhance recall. The picture superiority effect has important implications for various fields, including education, advertising, and communication, where the use of visual aids can enhance learning, memory, and comprehension. When faced with complex technical problems, visualizing the components, relationships, and processes involved can aid in understanding the problem better. Diagrams, charts, and graphs can help break down complex information into more digestible visual chunks, making it easier to identify patterns and solutions. Technical information presented in visual formats is more likely to be encoded into memory due to the picture superiority effect. This means that engineers, programmers, or technicians who encounter technical diagrams, schematics, or flowcharts are more likely to remember key details and procedures when solving problems.

Visual representations can make it easier to spot errors or anomalies within technical systems or processes. For example, analyzing graphs or charts of performance metrics may quickly reveal irregularities that indicate underlying technical issues. When working in teams to solve technical problems, visual representations can serve as a common language that facilitates communication and collaboration. Visual aids can help team members understand each other’s perspectives, share ideas more effectively, and collectively brainstorm solutions. In fields such as engineering and product development, visual representations play a crucial role in the design and prototyping stages. Engineers and designers often use diagrams, sketches, and 3D models to conceptualize and refine technical solutions before implementation.

1: Mass of the moving object: [’26: Amount of substance’, ’28: Accuracy of measurement’, ’29: Accuracy of manufacturing’, ’36: Complexity of the structure’, ’37: Complexity of control and measurement’, ’38: Level of automation’]

2: Mass of the non-moving object: [’13: Stability of the object’, ’25: Time loss’, ’26: Amount of substance’, ’28: Accuracy of measurement’, ’36: Complexity of the structure’, ’38: Level of automation’]

3: Length of the moving object: [’36: Complexity of the structure’, ’37: Complexity of control and measurement’, ’38: Level of automation’]

4: Length of the non-moving object: [’14: Strength’, ’24: Information loss’, ’36: Complexity of the structure’, ’37: Complexity of control and measurement’, ’39: Productivity’]

5: Area of the moving object: [’22: Energy loss’, ’24: Information loss’, ’25: Time loss’, ’28: Accuracy of measurement’, ’32: Convenience of manufacturing’, ’37: Complexity of control and measurement’, ’39: Productivity’]

6: Area of the non-moving object: [‘4: Length of the non-moving object’, ’28: Accuracy of measurement’]

7: Volume of the moving object: [‘1: Mass of the moving object’, ’28: Accuracy of measurement’, ’36: Complexity of the structure’, ’37: Complexity of control and measurement’]

8: Volume of the non-moving object: [’37: Complexity of control and measurement’]

9: Speed: [’14: Strength’, ’24: Information loss’, ’35: Adaptability’]

10: Force: [’36: Complexity of the structure’]

12: Shape: [‘2: Mass of the non-moving object’, ’15: Action time of the moving object’, ’33: Convenience of use’, ’39: Productivity’]

13: Stability of the object: [‘2: Mass of the non-moving object’, ’36: Complexity of the structure’]

14: Strength: [‘2: Mass of the non-moving object’, ‘4: Length of the non-moving object’, ‘9: Speed’, ’15: Action time of the moving object’, ’21: Power’]

15: Action time of the moving object: [’12: Shape’]

16: Action time of the non-moving object: [’28: Accuracy of measurement’]

17:Temperature: [’32: Convenience of manufacturing’, ’33: Convenience of use’, ’38: Level of automation’]

18: Brightness, Visibility: [‘5: Area of the moving object’, ’10: Force’, ’25: Time loss’, ’32: Convenience of manufacturing’, ’33: Convenience of use’, ’38: Level of automation’]

19: Energy consumption of the moving object: [’10: Force’, ’32: Convenience of manufacturing’]

21: Power: [‘2: Mass of the non-moving object’, ’10: Force’, ’14: Strength’, ’27: Reliability’, ’32: Convenience of manufacturing’, ’33: Convenience of use’]

22: Energy loss: [‘5: Area of the moving object’, ’14: Strength’]

24: Information loss: [‘3: Length of the moving object’, ‘4: Length of the non-moving object’, ‘5: Area of the moving object’, ‘9: Speed’, ’25: Time loss’]

25: Time loss: [‘2: Mass of the non-moving object’, ‘5: Area of the moving object’, ’18: Brightness, Visibility’, ’24: Information loss’, ’29: Accuracy of manufacturing’]

26: Amount of substance: [‘2: Mass of the non-moving object’]

27: Reliability: [’21: Power’, ’31: Harmful internal factors’]

28: Accuracy of measurement: [‘1: Mass of the moving object’, ‘2: Mass of the non-moving object’, ‘3: Length of the moving object’, ‘5: Area of the moving object’, ‘6: Area of the non-moving object’, ’16: Action time of the non-moving object’, ’22: Energy loss’, ’30: Harmful external factors’, ’37: Complexity of control and measurement’]

29: Accuracy of manufacturing: [’17:Temperature’, ’25: Time loss’, ’30: Harmful external factors’, ’31: Harmful internal factors’, ’36: Complexity of the structure’, ’38: Level of automation’]

30: Harmful external factors: [’28: Accuracy of measurement’, ’29: Accuracy of manufacturing’]

31: Harmful internal factors: [’28: Accuracy of measurement’, ’29: Accuracy of manufacturing’]

32: Convenience of manufacturing: [‘5: Area of the moving object’, ’17:Temperature’, ’19: Energy consumption of the moving object’, ’36: Complexity of the structure’]

33: Convenience of use: [’17:Temperature’, ’34: Convenience of repair’, ’36: Complexity of the structure’]

34: Convenience of repair: [’33: Convenience of use’]

35: Adaptability: [’18: Brightness, Visibility’]

36: Complexity of the structure: [‘1: Mass of the moving object’, ‘2: Mass of the non-moving object’, ‘3: Length of the moving object’, ‘4: Length of the non-moving object’, ‘7: Volume of the moving object’, ’10: Force’, ’28: Accuracy of measurement’, ’29: Accuracy of manufacturing’, ’32: Convenience of manufacturing’, ’33: Convenience of use’]

37: Complexity of control and measurement: [‘1: Mass of the moving object’, ‘3: Length of the moving object’, ‘4: Length of the non-moving object’, ‘8: Volume of the non-moving object’, ’18: Brightness, Visibility’, ’28: Accuracy of measurement’, ’34: Convenience of repair’]

38: Level of automation: [‘1: Mass of the moving object’, ‘2: Mass of the non-moving object’, ’17:Temperature’, ’28: Accuracy of measurement’, ’29: Accuracy of manufacturing’, ’32: Convenience of manufacturing’, ’39: Productivity’]

39: Productivity: [‘1: Mass of the moving object’, ‘4: Length of the non-moving object’, ‘5: Area of the moving object’, ’18: Brightness, Visibility’, ’38: Level of automation’]

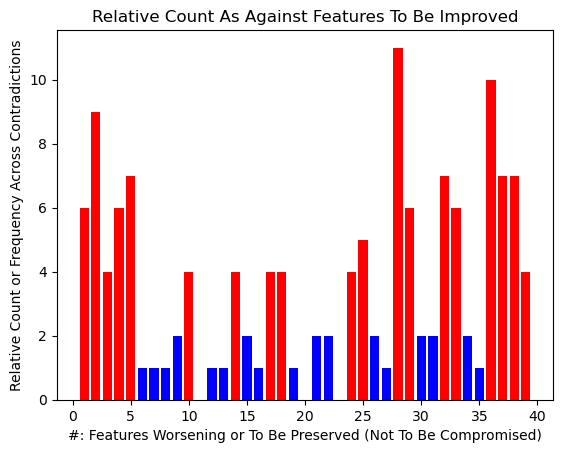

1/26 1/28 1/29 1/36 1/37 1/38 2/13 2/25 2/26 2/28 2/36 2/38 3/36 3/37 3/38 4/14 4/24 4/36 4/37 4/39 5/22 5/24 5/25 5/28 5/32 5/37 5/39 6/4 6/28 7/1 7/28 7/36 7/37 8/37 9/14 9/24 9/35 10/36 12/2 12/15 12/33 12/39 13/2 13/36 14/2 14/4 14/9 14/15 14/21 15/12 16/28 17/32 17/33 17/38 18/5 18/10 18/25 18/32 18/33 18/38 19/10 19/32 21/2 21/10 21/14 21/27 21/32 21/33 22/5 22/14 24/3 24/4 24/5 24/9 24/25 25/2 25/5 25/18 25/24 25/29 26/2 27/21 27/31 28/1 28/2 28/3 28/5 28/6 28/16 28/22 28/30 28/37 29/17 29/25 29/30 29/31 29/36 29/38 30/28 30/29 31/28 31/29 32/5 32/17 32/19 32/36 33/17 33/34 33/36 34/33 35/18 36/1 36/2 36/3 36/4 36/7 36/10 36/28 36/29 36/32 36/33 37/1 37/3 37/4 37/8 37/18 37/28 37/34 38/1 38/2 38/17 38/28 38/29 38/32 38/39 39/1 39/4 39/5 39/18 39/38

EXAMPLE: Displaying products in aesthetically pleasing and lifelike poses. The use of a mannequin in retail or fashion displays can be considered an application of the “Copying” inventive principle. The technical features or parameters involved in this context may be related to human representation, size, shape, and posture. Displaying clothing or products in a way that accurately represents how they would appear on a human body while maintaining consistency across various displays.

Contradiction (12/15 or 12/33 or 12/39): Human Representation (Shape -12) and Consistency of posture (Convenience – 33 and Productivty – 39)

Solution: The “Copying” inventive principle is applied in the use of mannequins to resolve the contradiction in retail displays by mimicking human features. This approach ensures a consistent and visually appealing representation of clothing items, contributing to a more immersive and relatable customer experience. The use of mannequins contributes to an enhanced customer experience by providing a more realistic and engaging representation of products. Customers can better assess the visual appeal and fit of clothing items, leading to informed purchasing decisions. Mannequins, through copying human shapes, sizes, and poses, allow for versatile visual merchandising. Retailers can adapt the mannequin’s appearance to match different demographics, fashion trends, or the targeted audience, addressing the need for flexibility and adaptability in product displays.

Accurately representing the fit and drape of clothing items. Mannequins are designed with human-like shapes and sizes to provide a realistic portrayal of how clothing would look on an actual person. This copying of the human form addresses the contradiction by ensuring consistency in showcasing various clothing items. Mannequins are often positioned in various poses that mimic natural human movements. Copying these poses helps create visually appealing displays that showcase the versatility and style of the clothing, addressing the contradiction of presenting products in a lifelike manner.

Providing a stable and durable support for clothing without compromising the visual appeal. Mannequins are engineered to be stable and durable while maintaining an aesthetically pleasing appearance. Copying the structural elements that provide stability from human anatomy ensures that the mannequin effectively supports the clothing without distracting from the overall presentation. The contradiction involves the challenge of presenting products in a way that resonates with customers, simulating how the items would appear on a human body. By copying the features of the human form, mannequins offer a consistent and relatable representation of clothing, aiding customers in visualizing the fit and style.