22: CONVERT HARM INTO BENEFITS : (A) Utilize (or transfer or direct) harmful factors – especially environmental – to an object (or system) to obtain a positive effect, (B) Remove (or reduce or eliminate sensitivity to) primary harmful factor by combining it with another harmful factor, (C) Increase the degree of harmful action to such an extent or degree or limit such that (or until) it ceases to be harmful.

EXAMPLE: Recycled paper or used or waste materials, Biofuel, Organic Fertilizers, Red Birth Mark Removal Introducing Green Pigments, High Decibel Music Note Superimposed over Noise, Explosive Excavation, Use waste heat to generate electric power, Overfreezing to make ice brittle, adding a buffer or buffering to prevent lags (ads) or avoid corrosion through contact (mediator).

SYNONYMS: BLESSING IN DISGUISE, Benefit from Harm, Turn Lemons Into Lemonade, Spin Harm to Gold, When life throws bricks at you, build your own mansion, Every Cloud Has a Silver Lining, Rising from the Ashes, Making a Silk Purse out of a Sow’s Ear, Finding Light in the Darkness, Phoenix Rising, Planting Seeds of Success in Failure, Building Bridges, Not Walls, Navigating Stormy Seas, Turning Negatives into Positives:

ACB:

“Blessing in Disguise” suggests that a problem or drawback in a system can be turned into an advantage if it is recognized and used in a creative way. Instead of viewing a disadvantage as purely negative, look for ways to leverage it for positive outcomes. Instead of seeing a problem as a purely negative aspect, consider how it might be reframed or redefined to provide a hidden opportunity or advantage. Identify ways in which a seemingly negative attribute or feature can be harnessed or transformed into a positive element for the system. This principle encourages thinking outside the box and finding innovative solutions by capitalizing on existing challenges or drawbacks. Look for components or aspects of a system that may have a dual function, serving both the primary purpose and an additional, unexpected benefit. Practical applications of this principle might include utilizing waste heat generated by a process for another useful purpose, turning a noise issue into a safety feature, or finding a positive use for a by-product that was initially considered undesirable. For instance: Spoiled milk can indeed be repurposed to make cottage cheese, as the fermentation process involved in spoilage aligns with the natural curdling process used in cottage cheese production. Cottage cheese is made by coagulating milk proteins, separating the curds from the whey. Factories often generate excess heat as a byproduct of their operations. Another nearby facility can use this excess heat for their own processes, reducing the need for additional energy sources. Industries generate wastewater containing various pollutants. The treated wastewater can be used by other industries for processes that don’t require high-quality water. For example, treated wastewater from a textile factory might be suitable for irrigation in agriculture.

The device where paddling or movement generates or stores energy, is commonly known as a “kinetic energy harvester” or “human-powered generator.” These devices capture the energy generated by human movement and convert it into electrical energy for various purposes. There are different types of kinetic energy harvesters, and they can be designed to harness energy from various human activities, including pedaling, walking, or even hand-cranking. Bicycle Generators are devices that use the pedaling motion of a bicycle to generate electricity. The energy generated by pedaling is converted into electrical power, which can be used to charge batteries, power lights, or run small electronic devices. Footstep Energy Harvesters devices are designed to capture the energy generated by people walking or running. They can be embedded in floor surfaces, such as in crowded areas or pedestrian walkways, and convert the mechanical energy from footsteps into electrical power.

Hand-Crank Generators are Portable generators with a hand-crank mechanism allow users to generate electricity by turning a crank. This can be useful in emergency situations, outdoor activities, or when a power source is not readily available. Piezoelectric Devices generate electrical energy in response to mechanical stress or vibrations (mechanical vibrations). These can be integrated into clothing, shoes, or other accessories to capture energy from body movements. The primary applications of kinetic energy harvesters include providing power in off-grid or remote locations, serving as backup power sources, and promoting sustainability by harnessing human-generated energy. These devices are often used in scenarios where conventional power sources may not be readily accessible, and they can contribute to reducing reliance on traditional energy grids in certain situations.

Some of these examples highlight how setbacks, mistakes, or unexpected outcomes can lead to valuable discoveries or innovations when viewed with a creative and open mindset. The “Blessings in Disguise” principle encourages looking for opportunities in apparent challenges, turning limitations into advantages:

Post-it Notes: Weak adhesive that initially seemed like a limitation. The weak adhesive of Post-it Notes, initially considered a drawback, turned out to be an advantage. It allowed users to attach notes to surfaces without leaving a sticky residue. Velcro Fasteners: Burrs sticking to clothing. Swiss engineer George de Mestral noticed burrs sticking to his dog’s fur and his clothing during a walk. Instead of seeing this as a nuisance, he turned it into an idea for creating Velcro fasteners, utilizing the principle of “blessings in disguise.” Microwave Oven: Magnetron melting a candy bar in Percy Spencer’s pocket. Percy Spencer discovered that microwaves from the magnetron melted a candy bar in his pocket. Instead of viewing it negatively, he saw the potential for cooking food with microwaves, leading to the invention of the microwave oven. Teflon Coating: Slippery substance causing issues in manufacturing. Teflon was initially challenging to work with due to its slippery nature. However, it was later found to be an excellent non-stick coating for cookware.

Viagra (Sildenafil): Originally developed for hypertension and angina. During clinical trials, it was discovered that Sildenafil, the active ingredient in Viagra, had an unexpected side effect—improving erectile dysfunction. This “blessing in disguise” led to the development of a widely used medication for treating impotence. Coca-Cola: Accidental creation of a syrup for headaches. Coca-Cola was initially created as a headache remedy. Its carbonation and refreshing taste, however, turned it into one of the world’s most popular beverages. Penicillin: Mold contaminating bacterial cultures in Alexander Fleming’s lab. : Alexander Fleming noticed that the mold (Penicillium) killed bacteria in the culture. This accidental discovery led to the development of the antibiotic penicillin, revolutionizing medicine.

Super Glue (Cyanoacrylate): Invented as a clear plastic for gun sights during World War II, it was too sticky for practical use. Despite the initial challenges, it was later marketed as a powerful adhesive, known today as Super Glue. Play-Doh: Originally developed as a wallpaper cleaner. When the demand for wallpaper cleaning decreased, Play-Doh was rebranded as a children’s toy modeling compound and became immensely popular. Safety Glass: Broken glass causing injuries in accidents. Laminated safety glass was developed by accident when a layer of celluloid was placed between two glass layers, preventing shards from scattering upon impact. Stainless Steel: Early attempts at corrosion-resistant steel were too brittle. The accidental discovery of stainless steel occurred when Harry Brearley found that a steel with 13% chromium resisted corrosion and retained its strength. WD-40: Developed as a water displacement solution for the Atlas Missile, initially intended for military use. When it was found to have various household uses, it was repurposed as a lubricant and rust-prevention product.

X-rays: Wilhelm Roentgen discovered X-rays accidentally while working with cathode rays. The accidental discovery revolutionized medical imaging, allowing for non-invasive visualization of internal structures. Silly Putty: Developed as a synthetic rubber substitute during World War II, but it didn’t serve its intended purpose. Silly Putty became a popular children’s toy after it was discovered that it had unique stretching and bouncing properties. Chemotherapy: Mustard gas exposure during World War I led to the realization that it suppressed the growth of white blood cells. This discovery laid the foundation for chemotherapy as a cancer treatment. Vienna Cake: Bakers in Vienna mistakenly used whipped egg whites instead of yeast in a cake. The result was a lighter and fluffier cake, leading to the creation of the famous Vienna Cake. Pacemaker: Engineer Wilson Greatbatch was working on building a device to record heart sounds. He mistakenly installed the wrong resistor, creating a pulse-generator circuit that led to the invention of the modern pacemaker.

It is also related to using harmful factors to achieve a positive effect, combining harmful factors to eliminate sensitivity, and increasing the degree of harmful action until it ceases to be harmful. Hydraulic Fracturing (Fracking): High-pressure injection of fluids (water, sand, and chemicals) into underground rock formations and using extraction of natural gas and oil from the rock formations. Bio-remediation: Introduction of specific microorganisms to contaminated environments and using microorganisms break down pollutants, leading to environmental cleanup. Vaccination: Introduction of a weakened or inactivated form of a pathogen and using immune system response, creating immunity to the pathogen, and preventing illness. Water Fluoridation: Addition of fluoride to drinking water and using ir for reduction in tooth decay and improved dental health. Heat Treatment in Metallurgy: Exposure of metal to high temperatures and using it for strengthening of the metal structure by rearranging its internal molecular arrangement. Selective Laser Trabeculoplasty (SLT) for Glaucoma: Application of laser energy to the trabecular meshwork in the eye and using it for improvement in drainage of intraocular fluid, reducing intraocular pressure and managing glaucoma.

Researchers and startups have explored ways to capture and utilize carbon emissions from various sources, including vehicle exhaust. One can capture carbon emissions from vehicle exhaust and converting them into a valuable material, such as black pigment. This approach aligns with the concept of carbon capture and utilization (CCU). While specific companies and technologies may vary, the general process involves several steps: Companies develop devices or technologies that can be integrated into vehicle exhaust systems to capture carbon emissions. This can involve installing specialized filters or catalysts designed to capture carbon dioxide (CO2) or other carbon compounds from the exhaust stream. Once captured, the collected carbon is then utilized rather than being released into the atmosphere. One utilization method involves converting the captured carbon into a useful material. In the context of creating black pigment, the captured carbon can be processed and transformed into a form suitable for use in pigments. This may involve chemical processes to refine and modify the carbon. The processed carbon material, now in the form of a black pigment, can be integrated into the manufacturing processes of companies that produce pigments. These pigments can then be used in various applications, such as coloring materials, paints, inks, and plastics. By capturing and utilizing carbon emissions, this approach contributes to reducing the overall carbon footprint associated with vehicle emissions. It provides a way to turn a potential waste stream (carbon emissions) into a valuable resource (black pigment).

Murphy’s Law: Murphy’s Law is the adage that “anything that can go wrong will go wrong.” While not strictly a cognitive bias, Murphy’s Law reflects a pessimistic outlook on the likelihood of technical failures or setbacks. In the context of designing a technical system, this bias might lead designers to focus excessively on worst-case scenarios or potential failure points, resulting in overly complex or redundant design features that detract from usability or efficiency. Similarly, when solving technical problems, individuals might be overly cautious or risk-averse, leading to delays or missed opportunities for innovation. While it’s important to anticipate and mitigate potential risks in technical design and problem-solving, an excessive focus on Murphy’s Law can hinder progress and innovation.

1: Mass of the moving object: [’30: Harmful external factors’, ’31: Harmful internal factors’]

2: Mass of the non-moving object: [’17:Temperature’, ’21: Power’, ’30: Harmful external factors’, ’31: Harmful internal factors’]

5: Area of the moving object: [’30: Harmful external factors’]

6: Area of the non-moving object: [’31: Harmful internal factors’]

7: Volume of the moving object: [’24: Information loss’, ’30: Harmful external factors’]

11: Tension, Pressure: [’30: Harmful external factors’]

12: Shape: [‘7: Volume of the moving object’, ’17:Temperature’, ’26: Amount of substance’, ’30: Harmful external factors’]

13: Stability of the object: [’12: Shape’, ’36: Complexity of the structure’, ’37: Complexity of control and measurement’]

14: Strength: [’31: Harmful internal factors’]

15: Action time of the moving object: [’30: Harmful external factors’, ’31: Harmful internal factors’]

16: Action time of the non-moving object: [’31: Harmful internal factors’]

17:Temperature: [‘1: Mass of the moving object’, ‘2: Mass of the non-moving object’, ’12: Shape’, ’14: Strength’, ’30: Harmful external factors’, ’31: Harmful internal factors’]

19: Energy consumption of the moving object: [’22: Energy loss’]

20: Energy consumption of the non-moving object: [’30: Harmful external factors’, ’31: Harmful internal factors’]

21: Power: [’11: Tension, Pressure’, ’30: Harmful external factors’]

22: Energy loss: [’30: Harmful external factors’, ’31: Harmful internal factors’]

23: Material loss: [‘2: Mass of the non-moving object’, ’30: Harmful external factors’]

24: Information loss: [‘8: Volume of the non-moving object’, ’30: Harmful external factors’, ’31: Harmful internal factors’, ’33: Convenience of use’]

25: Time loss: [’13: Stability of the object’, ’31: Harmful internal factors’]

28: Accuracy of measurement: [’30: Harmful external factors’]

30: Harmful external factors: [‘1: Mass of the moving object’, ‘2: Mass of the non-moving object’, ‘5: Area of the moving object’, ‘7: Volume of the moving object’, ‘9: Speed’, ’11: Tension, Pressure’, ’12: Shape’, ’15: Action time of the moving object’, ’17:Temperature’, ’20: Energy consumption of the non-moving object’, ’21: Power’, ’22: Energy loss’, ’23: Material loss’, ’24: Information loss’, ’35: Adaptability’, ’36: Complexity of the structure’, ’37: Complexity of control and measurement’, ’39: Productivity’]

31: Harmful internal factors: [‘1: Mass of the moving object’, ‘2: Mass of the non-moving object’, ‘3: Length of the moving object’, ‘6: Area of the non-moving object’, ’14: Strength’, ’15: Action time of the moving object’, ’16: Action time of the non-moving object’, ’17:Temperature’, ’20: Energy consumption of the non-moving object’, ’22: Energy loss’, ’25: Time loss’, ’39: Productivity’]

33: Convenience of use: [’24: Information loss’]

35: Adaptability: [’18: Brightness, Visibility’]

36: Complexity of the structure: [’13: Stability of the object’, ’30: Harmful external factors’]

37: Complexity of control and measurement: [’13: Stability of the object’, ’24: Information loss’, ’30: Harmful external factors’]

39: Productivity: [’13: Stability of the object’, ’30: Harmful external factors’, ’31: Harmful internal factors’]

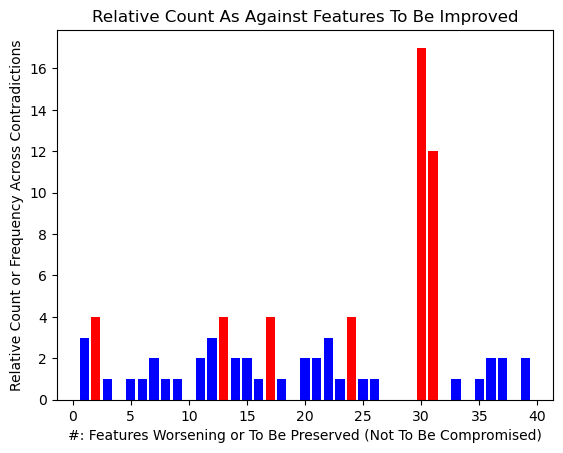

1/30 1/31 2/17 2/21 2/30 2/31 5/30 6/31 7/24 7/30 11/30 12/7 12/17 12/26 12/30 13/12 13/36 13/37 14/31 15/30 15/31 16/31 17/1 17/2 17/12 17/14 17/30 17/31 19/22 20/30 20/31 21/11 21/30 22/30 22/31 23/2 23/30 24/8 24/30 24/31 24/33 25/13 25/31 28/30 30/1 30/2 30/5 30/7 30/9 30/11 30/12 30/15 30/17 30/20 30/21 30/22 30/23 30/24 30/35 30/36 30/37 30/39 31/1 31/2 31/3 31/6 31/14 31/15 31/16 31/17 31/20 31/22 31/25 31/39 33/24 35/18 36/13 36/30 37/13 37/24 37/30 39/13 39/30 39/31

EXAMPLE: Organic waste from food processing or agricultural residues or from cateteria of the companies: Turning food waste into bioenergy is a sustainable practice that can benefit both the environment and the company itself. The process often involves anaerobic digestion, a biological process where microorganisms break down organic matter in the absence of oxygen. Biomass can be converted into bioenergy or used as a raw material for producing bio-based products, such as biofuels, fertilizers, or even biodegradable packaging materials. Compliance with environmental regulations and permitting is crucial for implementing such systems. Companies need to invest in appropriate technology for anaerobic digestion and energy conversion. Implementing an on-site anaerobic digestion system allows companies to convert their food waste into a valuable resource, contributing to environmental sustainability and potentially providing a portion of the facility’s energy needs.

Contradiction (2/30, 2/31, 23/30, 31/22:, 31/2): Reduce or make the best use of the the material loss (wasted food and related harmful factors) while not spending additional energy or cost on it.

Solution: The company collects food waste generated during its operations. This can include kitchen scraps, expired or unsold food products, and other organic materials.The collected food waste may undergo preprocessing to remove contaminants like plastic or non-organic materials. Larger items may be shredded or ground into smaller pieces to facilitate the digestion process. The preprocessed food waste is fed into an anaerobic digester, which is a sealed container where microorganisms break down the organic matter in the absence of oxygen. In the digestion process, bacteria break down complex organic compounds into simpler substances, producing biogas as a byproduct. The main component of biogas is methane, which is a valuable renewable energy source. Methane can be used for various applications, including electricity generation and heating. The biogas produced during anaerobic digestion is captured and stored in a separate chamber or system. This prevents the release of methane into the atmosphere, as methane is a potent greenhouse gas. The captured biogas can be used as fuel in a combined heat and power (CHP) system or a biogas generator to produce electricity and heat. Alternatively, the biogas can be used directly for heating purposes in the facility.

The remaining material after digestion, known as digestate, is a nutrient-rich organic material. Depending on its characteristics, the digestate can be used as a fertilizer for agricultural purposes. The bioenergy produced from food waste is renewable and reduces the dependency on non-renewable energy sources. The process helps in diverting food waste from landfills, reducing methane emissions associated with food decomposition. The digestate, if used as fertilizer, closes the loop by returning nutrients to the soil for agricultural production. The efficiency of the anaerobic digestion process depends on factors such as waste composition, digester design, and operational conditions.